Though I’m fortunate to have a large workshop space, I’d still be constrained by not having enough room to position my larger tools in unobstructed floor positions. My solution?

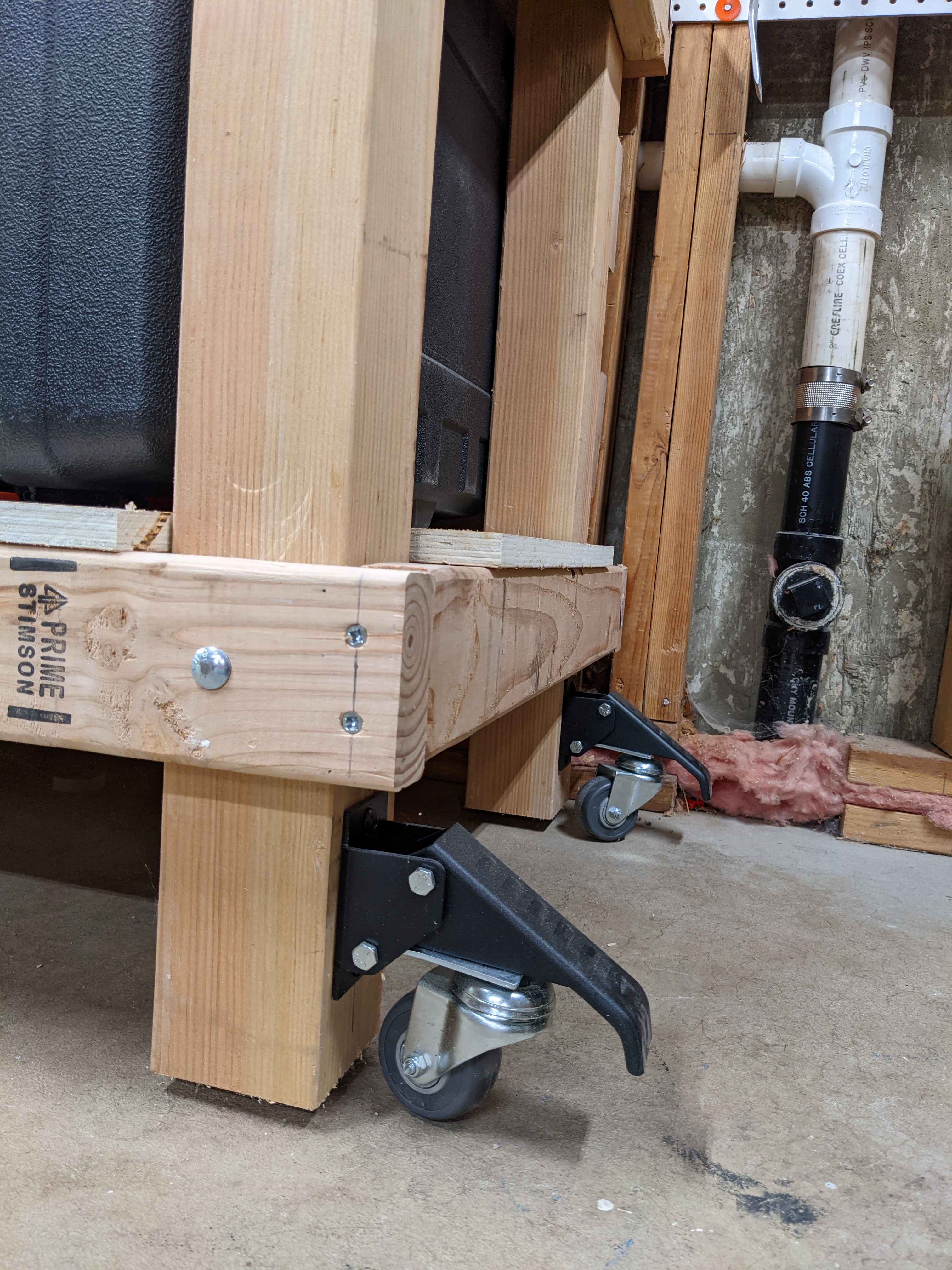

Wheels! Specifically, rolling mobile bases and caster kits. The mobile bases can support large, heavy, “stationary” tools when properly adjusted / modified. The caster kits can be attached to workbenches, etc. for easy mobility. I’m using these on my table saw, band saw, jointer, planer, and small workbench. The mobile bases are available in different configurations (weight limits, size) and offer extensions and other options. The bases sacrifice support outside the corners for build flexibility, requiring custom solutions noted below.

Installing the band saw was tricky since the weight had to be supported in the middle and at the edge due to the extended stand supports. I ended up purchasing two 1/2 inch A36 custom steel plates to span the length for stable support. Works like a charm; strike up the band (saw)!

The table saw and jointer required wood and supporting thin plate to bring the leg supports in from the corners.

The planer was a bit easier. DeWALT sells a mobile planer stand that’s not quite as flexible but still recommended (more restricted in adjusting position due to three wheels).

These large tools and my smaller workbench are easy to move. And quite stable when the foot levers are in the locked position. The added flexibility has made my large workshop even larger!

Just remember to assemble the tool on top of the base from the start! Yes, you’ll be excited to have a new tool and you’ll worry about the base later. But lifting a heavy tool onto a framed platform isn’t something I’d recommend (though I’ve done it and still regret having my friends help me with those lifts).